Description

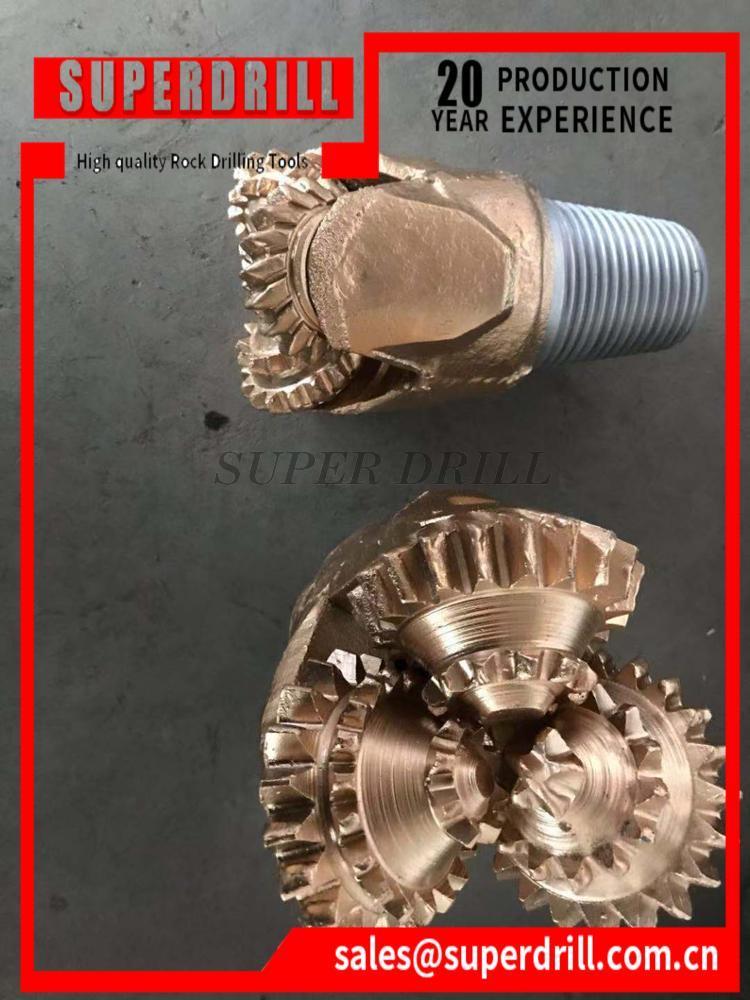

Tricone Drill Bit Oil Gas Well Mining Rock Drilling

Tricone bits are used in construction engineering, water well drilling, gas and oil development, blast hole creation, and seismic prospecting.Currently, tricone rock pieces come in eleven common varieties.

IADC CODE for the steel teeth series is 116,117,126,127,136,137,216,217,317, and 337.

TCI series: 417,437,447,517,527,537,547,617,627,637,647,737,837 are the IADC CODEs.

Steel teeth roller bit, TCI tricone bit, TCI roller bits, roller bit, TCI tricone bit

1. The sizes ranged from 26" to 3 7/8"

2. Almost all IADC code is covered. 3. Dependable quality and affordable cost

Normal IADC:

437Soft Formation TCI Tricone Bits:

The 437 TCI bits are used to drill low compressive strength, very soft formations. TCI bits maximize the use of both conical and chisel tungsten carbide inserts of large diameters and high projection. This cutting structure design, combined with maximum cone offset, results in high bit penetration rates. The deep intermesh of cutter rows prevents bit bailing in sticky formations.

517Medium Formation TCI Tricone Bits:

The 517 features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium-to-medium hard formation. The HSN rubber O-ring provides adequate sealing for bearing durability.

637Hard Formation TCI Tricone Bits:

The 637 bits can be used to drill hard and abrasive formation. Wear-resistant tungsten carbide inserts are used in the outer rows to prevent loss of bit gauge. Maximum numbers of hemispherical-shaped inserts are used in all rows to provide cutter durability and long life.

617Medium-Hard Formation TCI Tricone Bits:

The 617 features robust chisel tungsten carbide inserts on the heel row and conical on the inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard formations. The HSN rubber O-ring provides adequate sealing for bearing durability.

Mobile:

Mobile: E-mail:

E-mail: